BEFORE INSTALLATION, REMEMBER TO…

- Check local fence codes.

- Have utilities marked

- Measure and plan area.

- Clear fence path of obstructions

- Reserve your tool rental if needed.

- Buy Quickrete and have delivered.

- Unpack material and take inventory.

TOOLS & MATERIALS YOU WILL NEED…

- Post hole digger

- Shovel

- Level

- Hack saw

- Tape measure

- Electric screwdriver

- Hammer

- String line

- Wheelbarrow

- Quickrete

- Ground stakes

- Gravel

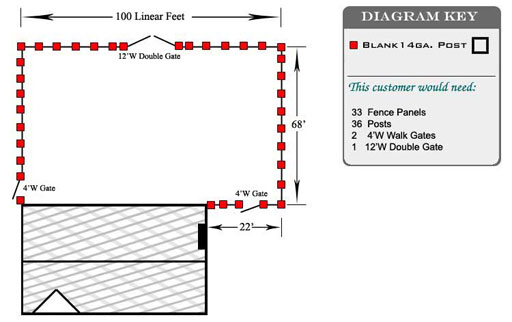

Step 1. Stake string lines for each run

Determine corner and end post locations. Drive stakes into the ground a few feet beyond that point so the string lines can cross making a 90° angle.

Run a tight string line between stakes to mark the fence line. The stakes should be tall enough so the string does not touch the ground.

Step 2. Set all of your posts in concrete

Dig holes at least 6″ in diameter and 2′ deep depending on size of posts. Scoop loose dirt out of the hole and measure to check depth. If too shallow, keep digging, if too deep add some loose gravel. Set post in hole and measure to assure proper depth.

Shovel your mixed concrete around post; fill to 4″ below ground level. Pack the excavated dirt tight around post, this will help keep your post from moving. Make sure the post is plumb against the string line and check for levelness.

HELPFUL HINT: Due to the weight of the wrought iron fence panels it is advised to wait a few days for the concrete to dry before attaching the fence sections to the posts.

Step 3. Attach fence panels to the posts

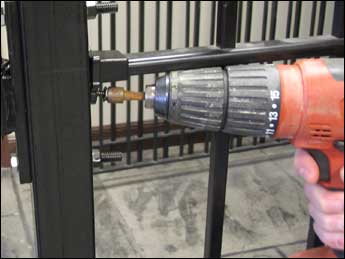

Slide your brackets over the end of the horizontal rails of the fence panel. Hold panel up between posts taking notice of the distance you want the fence off of the ground. Keep a hacksaw nearby in case you need to trim the panel down to fit between the posts.

While the fence panel is being held in place get your cordless drill with the appropriate bit and self tapping screws provided. Then starting with the top brackets screw them to the posts; next do the bottom brackets.

HELPFUL HINT: Check the fence run every couple of panels as you are installing it to ensure that the rails are matching up. This will give you a nice flow to the fence and make it look continuous.

Step 4. Hang gates and attach gate latch

To determine gate opening between gate posts, add the width of the gate to the following hardware allowances: 5″ J-Bolt Hinge = 3.5″ hardware allowance; 7″ J-Bolt = 4.5″ hardware allowance; Gravity Latch = 2.5″ hardware allowance; Magna-Latch = .75″ hardware allowance.

It is advised to wait 7 days before hanging your gates. If this is not possible and you have to hang the gates sooner, at least wait 7 days before the gate is used heavily.

The standard hinge included with our wrought iron gates are J-Bolt Hinges. It comes with two parts; a male shaped like an “L” and a female welded to a plate. You can install like the picture above or flip it around and bolt the female to the gate frame.

A gravity latch is included standard with our wrought iron gates. Very simple to install, just make sure the bar is screwed to the gate frame and the catch piece to the gate post. A small padlock can be added to the catch piece for added security.

How to handle “special situations”

Hillsides & Slopes

With wrought iron fencing there is only one way to handle hills and slopes; you have to step the fence. Longer posts will need to be ordered and you use the provided brackets to attach each panel at the bottom of the uphill post to achieve each “step”.

Cut Sections

With most installations there will be an fence line that will not fit a full section and it will need to be cut. This is a simple task and can be accomplished with a hacksaw. A section can always be trimmed down but cannot be easily extended to fit.

Attaching To A Wall

The above picture shows wall brackets attached to the corner of a brick house. Wall brackets are very useful in this application and also when you want to attach to columns, wood, or blank posts.

Installing On Concrete

To install a fence on top of a concrete pad you will need to either core drill or use concrete anchors in conjunction with a welded plate on your post. Core drilling gives you a cleaner finish but is more difficult.

Learn More about our Wrought Iron Fencing models.